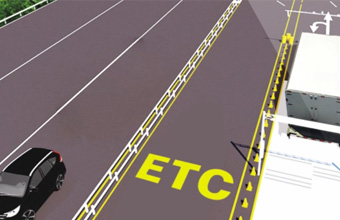

The entrance control system is mainly composed of quartz weighing sensor, weighing controller, charge amplifier, infrared vehicle separator and other equipment. The load cell mainly completes the work of vehicle weight measurement, speed detection, axle type judgment, etc.; the infrared vehicle separator is used to separate the vehicle and provide signals such as start and end; the charge amplifier is used to collect the charge signal and convert it into the required signal of the instrument. Weight; the weighing controller is used to process the signals from various sensors, calculate the data, and connect with the lane computer through the serial communication interface, and upload the processed lane weight information (including total weight, axle weight, etc.) to the lane computer .

1. Weighing vehicles passing at low speed;

2. Detect the speed of the vehicle when it passes through the lane, and can detect the forward/backward status of the vehicle;

3. Automatically separate the vehicles, accurately realize the separation of special vehicles such as trailers, and ensure the one-to-one correspondence between the weighing detection data and the vehicles;

4. Form complete vehicle weighing information, including axle type, axle weight, wheelbase, total vehicle weight and other information;

5. Record the passing time of vehicles;

6. Accurately and completely transmit the weighing information to the lane computer (host computer) through the data interface;

7. With power-on self-test, timed self-test when idle, zero point correction and automatic temperature compensation;

8. The digital instrument display panel can be used for debugging and testing, and the axle type, axle load and vehicle speed of each axle can be displayed on the panel.